MAN TGS WW ON THE BUILDING SITE

More power, less fuel

Improved dynamics with less fuel consumption, a longer service life with less maintenance: Engine outputs of between 360 HP and 540 HP are available, driven by efficient MAN six-cylinder in-line Common Rail engines from the D20 and D26 series. The engines meet the Euro 2, 3 or Euro 4 exhaust-gas standards, depending on local licensing regulations. MAN's impressive engines boast the lowest power-to-weight ratio in their class and a mileage of 1.5 million kilometres with maintenance intervals every 120,000 kilometres.

All the engines in MAN TGS WW trucks are designed for use in extreme climates. A large radiator, which is concealed beneath the front of the vehicle, is the key factor here. This enables the TGS WW to be used efficiently, both in hot climates and in colder regions where temperatures can reach as low as -50 °C.

| Displacement | Euro 2 | Euro 3 | Euro 4 | |

|---|---|---|---|---|

| D2066 | 10.5 l | |||

| 265 kW (360 HP), 1,800 Nm | X | X | X | |

| 294 kW (400 HP), 1,900 Nm | X | X | X | |

| 324 kW (440 HP), 2,100 Nm | X | X | ||

| D2676 | 12.4 l | |||

| 324 kW (440 HP), 2,100 Nm | X | |||

| 353 kW (480 HP), 2,300 Nm | X | X | X | |

| 397 kW (540 HP), 2,500 Nm | X |

Always in the right gear

The 16-gear gearbox with ServoShift system is comfortable to use and highly accurate. It is easy to shift and has short shifting distances. Changing gears with the fully automatic 12-gear MAN TipMatic® gearbox is extremely smooth. The clutch pedal has been removed and there is no need to engage the clutch or change gears manually. Furthermore, economical driving in automatic mode reduces fuel consumption. Gears can also be changed manually using a touch-action lever, if desired. The optional off-road mode has been specially tailored to heavy-duty traffic and makes driving on rough terrain in automatic mode more comfortable.

Improved efficiency: MAN TipMatic® – including off-road driving

The twelve-speed MAN TipMatic® semi-automatic gearbox creates a perfect synthesis of comfort and efficiency. The gearbox can be operated effortlessly either fully automatically or manually using the touch-action lever on the steering wheel. The clutch pedal has been removed and no gear stick is required. The driver is not distracted and can fully concentrate on the road. The kick-down function guarantees optimum ride dynamics.

The MAN TipMatic® with cross-country drive mode has been specifically designed for use on building sites and mining sites. It allows the MAN TGS WW to drive off-road comfortably in automatic mode. The gear shifting strategy with faster shifting times is key here. The selected gear is engaged for as long as possible to prevent the driver from having to continuously shift gears while driving at virtually the same speed. A higher torque is therefore available on start-up. The faster opening and closing of the clutch also makes it easier to rock free a truck that has become stuck.

The ZF torque converter clutch (WSK440) combined with a ZF TC-Tronic®, which can move a gross combined weight of up to 250 tonnes, has been specially designed for international heavy-duty transport.

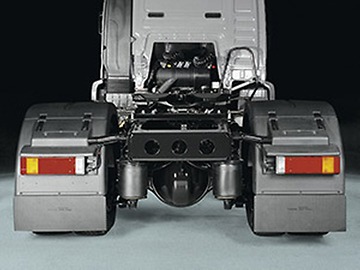

All-wheel drive for everyday driving

The MAN TGS WW with permanent or selectable all-wheel drive is brought into action wherever maximum traction is required. The two-gear MAN distributor gearbox with on-road and off-road gears distributes power evenly.

All-wheel drive vehicles also boast AP axles with good ground clearance, differential locks, hub brakes and stabilisers.

EVB engine brake

All engines are fitted with the wear-free EVB engine brake as standard. This system increases engine braking power by up to 60 percent more than a normal exhaust throttle flap. The engine brake lengthens the service life of the brake pads and significantly increases continuous braking power, thereby improving the active safety of the truck and the driver.

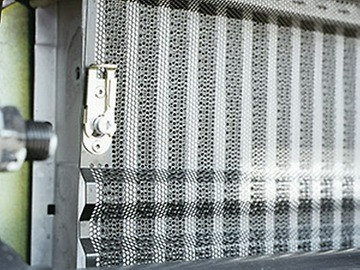

Stone guard on the radiator grille

Stone guards on the radiator protect it when driving on stony, unsurfaced tracks. Protective grilles on the headlights, rear lights and on the fuel tank also improve the safety of the TGS WW, especially on rough terrain.

Well-sprung axles

Normal-height MAN TGS WW vehicles that are predominantly used on the roads are fitted with disc-braked hypoid axles and maintenance-free radial bearings. They are characterised by their ability to carry heavy loads while weighing very little, running quietly and saving fuel.

The leaf-sprung front axle also impresses with its extremely low weight in comparison with its maximum axle load.

The maintenance-free ECAS air suspension is perfect for increasing driving comfort, transporting goods carefully and improving driving safety.

MAN provides the TGS WW in medium-height and high designs in order to increase the ground clearance under the planetary axles. There are the 4x2, 4x4, 6x4, 6x6, 8x4 and 8x8 drive versions to choose from, each with leaf-spring suspension and a large tyre. The TGS WW 6x4 is also available with 13-tonne four-bag air suspension, which is common throughout Europe.

There are two types of suspension available for particularly heavy vehicles: Parabolic leaf springs for increased driving comfort when travelling both with and without a load, and trapeze springs for use in extreme conditions.

Well-built for the mining industry

The demands placed on mining trucks are high: Tough multiple shift work with extremely high daily delivery rates, the heaviest loads, rough terrain and high dust exposure put the vehicle and the driver to the test every day. Mining trucks therefore need to be extremely robust, have a high payload, be fitted with powerful engines, be cost-effective to run and demonstrate high reliability – all at the same time. The new MAN TGS WW 50.440 8x4 BB meets all these requirements in full.

The enormous 50-ton payload is specially designed for taking metal ores and coal away from surface mines. A reinforced subframe allows the permissible gross vehicle weight to be increased. Safety is a top priority, which is why the truck is fitted with MAN BrakeMatic®electronic brake management and the powerful MAN PriTarder® sustained-action braking system. An ESP is available as an option.

A sturdy chassis makes a good base

The chassis, made from high-strength fine-grained steel, combines high torsional strength and flexural rigidity with maximum stability, a low weight and good body-mounting capability. The completely even top edge of the frame allows all types of superstructures to be mounted quickly, easily and economically.

The narrow hole pattern makes it possible to carry out subsequent extensions and conversions easily and without the need for additional time-consuming drilling work. The paint system with environmentally friendly water-based paints guarantees reliable corrosion protection for parts of the frame and chassis.